industrial gas furnace

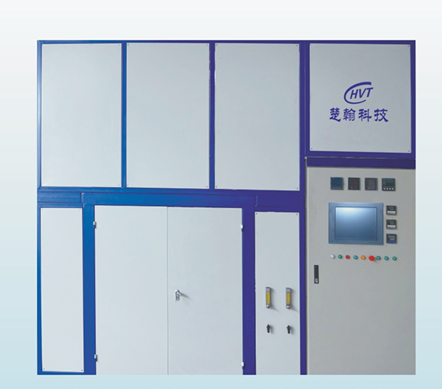

The industrial gas furnace represents a cornerstone of modern manufacturing and thermal processing operations. This sophisticated heating system utilizes natural gas or propane as its primary fuel source to generate controlled, high-temperature environments essential for various industrial processes. The furnace operates through a precisely engineered combustion system that ensures optimal fuel efficiency and temperature uniformity. Modern industrial gas furnaces incorporate advanced control systems that enable precise temperature regulation, ranging from 300°F to over 2000°F, making them suitable for diverse applications. These furnaces feature multiple heating zones, automated loading systems, and sophisticated safety mechanisms that monitor gas flow, temperature, and pressure levels. The technology includes programmable logic controllers (PLCs) that maintain consistent heating profiles and enable automated operation sequences. Applications span across numerous industries, including metal heat treatment, ceramic processing, glass manufacturing, and chemical production. The furnace's design typically includes refractory-lined chambers, high-velocity burners, and advanced insulation materials that maximize heat retention and energy efficiency. Environmental considerations are addressed through low-NOx burners and heat recovery systems that reduce emissions and energy consumption.