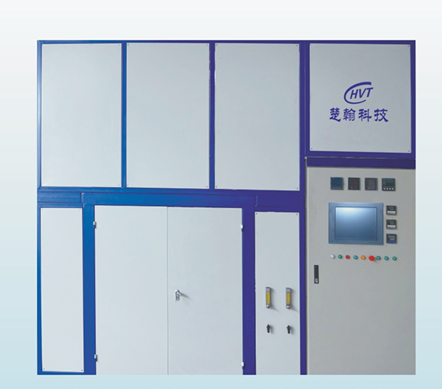

industrial metal furnace

The industrial metal furnace represents a cornerstone of modern manufacturing, serving as a sophisticated heating system designed for processing various metals and alloys. This advanced equipment operates at precisely controlled temperatures, ranging from 600°F to over 3000°F, making it essential for numerous metallurgical processes. The furnace incorporates state-of-the-art heating elements, advanced insulation materials, and precise temperature control systems to ensure optimal performance. Its primary functions include metal melting, heat treatment, annealing, and stress relieving of metal components. The furnace features multiple heating zones, automated temperature regulation, and energy-efficient operations, allowing for consistent and reliable results. Modern industrial metal furnaces are equipped with digital control interfaces, providing real-time monitoring and adjustment capabilities. These systems often include safety features such as emergency shutoffs, temperature limiters, and protective atmospheres to prevent oxidation. The furnace's versatility allows it to handle various metal types, from steel and aluminum to precious metals, making it indispensable in industries such as automotive manufacturing, aerospace, construction, and metal processing. Advanced models incorporate energy recovery systems and automated material handling capabilities, significantly improving operational efficiency and reducing energy consumption.