industrial furnace company

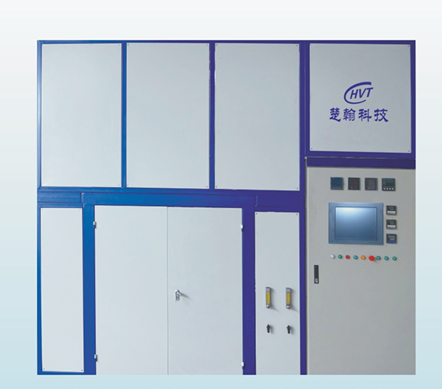

Our industrial furnace company stands at the forefront of thermal processing technology, delivering cutting-edge solutions for diverse manufacturing needs. With over two decades of expertise, we specialize in designing and manufacturing high-performance industrial furnaces that combine precision temperature control with energy efficiency. Our furnaces incorporate advanced digital monitoring systems, ensuring consistent heat distribution and optimal processing conditions. The product range includes batch furnaces, continuous processing furnaces, and custom-engineered solutions capable of reaching temperatures up to 2000°C. Each unit features state-of-the-art insulation materials and intelligent control systems that minimize energy consumption while maximizing productivity. We serve various industries, including aerospace, automotive, metallurgy, and ceramics, providing specialized heating solutions for heat treatment, sintering, annealing, and material testing applications. Our furnaces are equipped with multiple safety features, including emergency shutdown systems and temperature uniformity controls, ensuring reliable and safe operation. The modular design approach allows for easy maintenance and future upgrades, while the robust construction ensures long-term durability and consistent performance.