industrial furnace parts

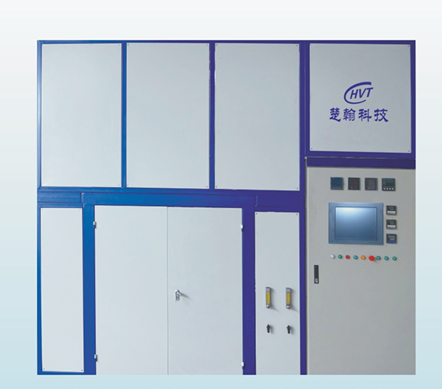

Industrial furnace parts represent critical components that form the backbone of thermal processing systems across various manufacturing sectors. These essential elements include heating elements, refractory materials, temperature sensors, control systems, and ventilation components, all working in harmony to ensure optimal furnace performance. The main function of these parts is to maintain precise temperature control, ensure energy efficiency, and provide consistent heat distribution throughout the furnace chamber. Advanced technological features incorporate state-of-the-art digital controls, automated monitoring systems, and smart sensors that enable real-time temperature adjustment and process optimization. These parts are engineered to withstand extreme temperatures while maintaining structural integrity and operational efficiency. Applications span across multiple industries, including metal processing, ceramic manufacturing, glass production, and heat treatment facilities. Modern industrial furnace parts often feature modular designs for easy maintenance and replacement, reducing downtime and operational costs. The integration of sophisticated insulation materials and cooling systems helps maximize energy utilization while ensuring safe operation. These components are designed to meet strict industry standards and regulations, incorporating safety features such as emergency shutdown systems and temperature limiters.