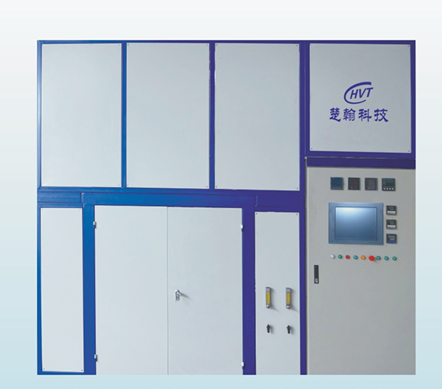

rotary furnace for heat treatment

A rotary furnace for heat treatment represents a sophisticated thermal processing system designed to deliver precise and uniform heating across various materials. This cylindrical apparatus features a rotating drum mechanism that ensures even heat distribution throughout the treatment process. The furnace operates by combining controlled temperature regulation with continuous material movement, allowing for consistent heat exposure across all treated components. The system typically incorporates advanced thermal insulation, precise temperature control mechanisms, and automated material handling capabilities. These furnaces can achieve temperatures ranging from 300°C to 1200°C, depending on the specific model and application requirements. The rotation speed can be adjusted to optimize heat transfer and processing time, making it suitable for various heat treatment processes including annealing, tempering, and stress relieving. The technology particularly excels in processing bulk materials and components that require uniform heat exposure. Applications span across multiple industries, including metallurgy, ceramics manufacturing, and advanced materials processing. The furnace's design also includes safety features such as emergency shutdown systems and temperature monitoring equipment to ensure reliable operation.