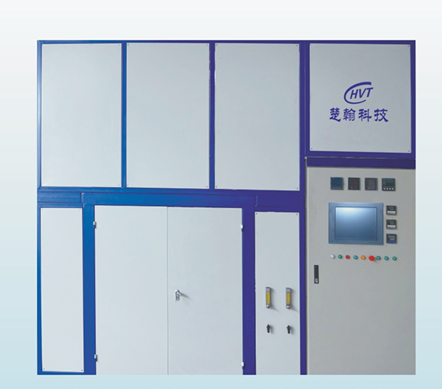

lab vacuum furnace

A lab vacuum furnace represents a sophisticated piece of scientific equipment designed for conducting high-temperature thermal processes in a controlled, vacuum environment. This advanced system combines precise temperature control with vacuum technology to achieve exceptional results in materials processing and research applications. The furnace operates by removing air and other atmospheric gases from the heating chamber, creating an environment free from oxidation and contamination. With operating temperatures typically ranging from 1000°C to 3000°C, these furnaces feature robust heating elements, usually made from molybdenum or tungsten, surrounded by multiple layers of heat shields. The vacuum system typically incorporates both mechanical and diffusion pumps to achieve high or ultra-high vacuum levels, often reaching 10-5 to 10-6 torr. Modern lab vacuum furnaces come equipped with programmable controllers for accurate temperature profiles, vacuum level monitoring, and automated operation sequences. These systems find extensive applications in materials science, metallurgy, ceramics research, and semiconductor processing, enabling crucial processes such as sintering, brazing, annealing, and heat treatment of sensitive materials.