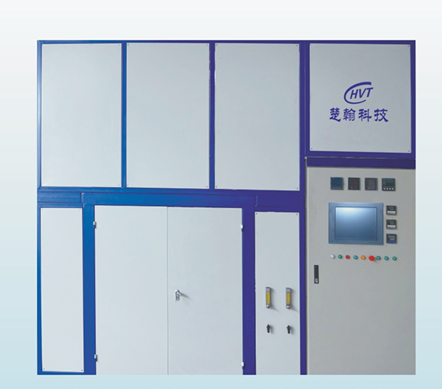

industrial heat treat furnace

An industrial heat treat furnace is a sophisticated piece of manufacturing equipment designed to alter the physical and chemical properties of materials through controlled temperature manipulation. These advanced systems utilize precise heating and cooling processes to enhance material characteristics such as hardness, strength, and durability. The furnace operates by creating a carefully controlled environment where temperatures can range from 300°F to over 2000°F, depending on the specific application and material requirements. Modern industrial heat treat furnaces incorporate advanced digital controls, multiple temperature zones, and sophisticated monitoring systems to ensure consistent and reliable results. These furnaces can accommodate various materials, including metals, alloys, and ceramics, making them essential in industries such as automotive manufacturing, aerospace, tool making, and metal fabrication. The equipment features advanced insulation systems, efficient heating elements, and precise temperature control mechanisms that work in harmony to deliver optimal heat treatment results. Additionally, these furnaces often include automated loading systems, programmable control interfaces, and data logging capabilities for process verification and quality control purposes.