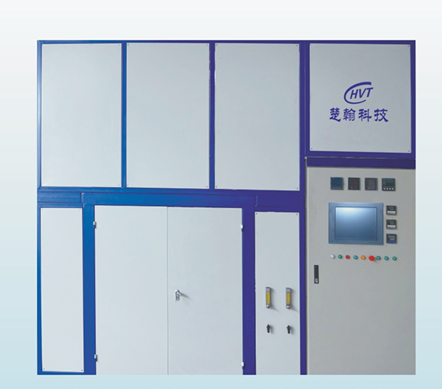

vacuum melting furnace

A vacuum melting furnace is a sophisticated metallurgical equipment designed to produce high-purity metals and alloys under controlled vacuum conditions. This advanced system operates by removing atmospheric gases and impurities from the melting chamber, ensuring superior metal quality and consistency. The furnace employs electromagnetic induction heating technology to melt metals while maintaining a vacuum environment, typically at pressures below 10-3 torr. The process involves charging raw materials into a water-cooled copper crucible, evacuating the chamber, and then initiating the melting sequence through precisely controlled power inputs. The vacuum environment prevents oxidation and contamination while allowing for the removal of dissolved gases and volatile impurities through degassing. Modern vacuum melting furnaces are equipped with advanced control systems that monitor and adjust temperature, pressure, and power parameters in real-time. These systems can accommodate various metal types and sizes, from small laboratory-scale operations to industrial-scale production. The technology finds extensive applications in aerospace, medical implants, electronics, and specialized metallurgy sectors where material purity is paramount.