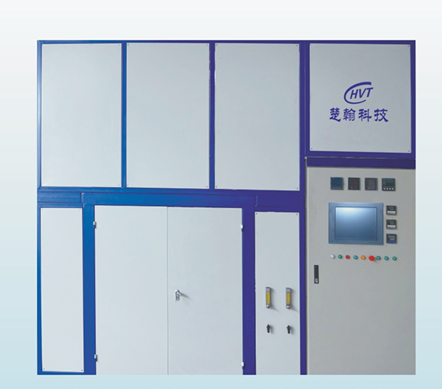

vacuum casting furnace

A vacuum casting furnace represents a sophisticated piece of industrial equipment designed to perform high-precision metal casting operations in a controlled, vacuum environment. This advanced system combines cutting-edge technology with precise environmental control to produce superior quality castings. The furnace operates by creating a vacuum within the casting chamber, effectively removing air and other gases that could potentially compromise the quality of the final product. This process is particularly crucial when working with reactive metals or applications requiring exceptional purity. The system typically consists of a sealed chamber, vacuum pumps, temperature control systems, and specialized monitoring equipment to ensure optimal casting conditions. The technology enables the production of complex metal components with minimal defects, superior surface finish, and enhanced mechanical properties. The vacuum environment prevents oxidation during the melting and casting process, resulting in higher quality output compared to traditional casting methods. These furnaces are equipped with advanced control systems that allow for precise temperature regulation, timing control, and process monitoring, making them suitable for both research and industrial applications. The versatility of vacuum casting furnaces makes them invaluable in industries such as aerospace, automotive, medical device manufacturing, and precision engineering, where component quality and material integrity are paramount.